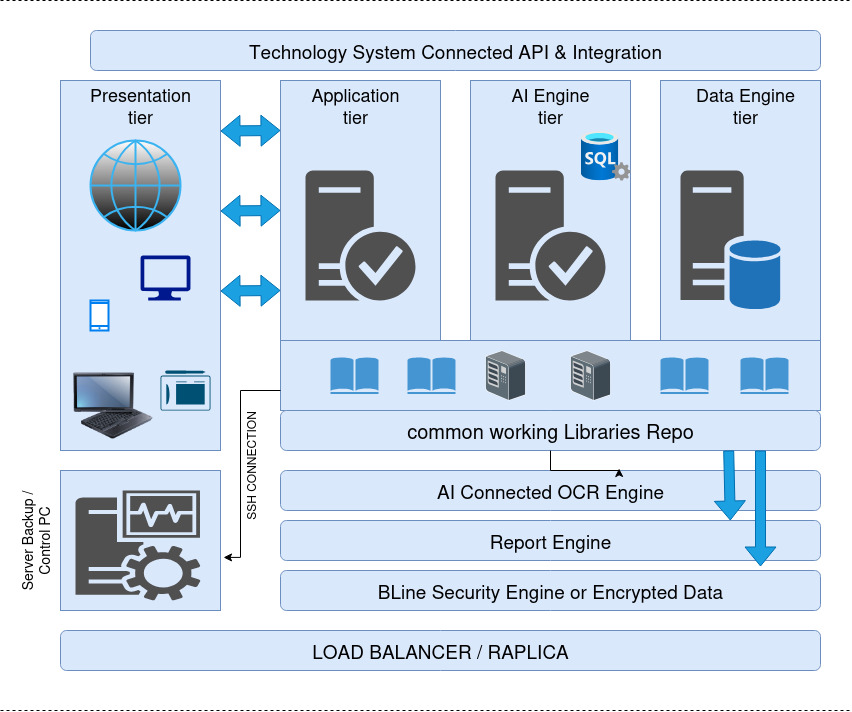

DEVELOPMENT FRAMEWORK

![]()

Development Methodology:

SN | Framework Activities | Action |

1. | Discovery, Planning & Design |

|

2. | Development & Testing |

|

3. | Implementation & User Training |

|

API Integration Methodology:

SN | Framework Activities | Action |

1. | Discovery, Planning & Design |

|

2. | Development & Testing |

|

3. | Implementation & User Training |

|

IoT Integration Methodology:

SN | Framework Activities | Action |

1. | Discovery, Planning & Design |

|

2. | Development & Testing |

|

3. | Implementation & User Training |

|

Platform Architecture