Digital B-Line Suite - Compliance with Global Regularities Body

VALIDATION CONSULTING SERVICES

Our validation experts provide end-to-end support to ensure your computerized systems comply with global regulatory requirements while minimizing business risks, stabilizing manufacturing processes, and ensuring product safety.

– Validation Master Plan (VMP) Development – Comprehensive validation strategy.

– Risk-Based Validation Approach – GAMP 5 Category determination.

– Regulatory Requirement Assessment – FDA 21 CFR Part 11, EU Annex 11, PIC/S.

1 User Requirements Specification (URS)

2 Installation Qualification (IQ)

3 Operational Qualification (OQ)

4 Performance Qualification (PQ)

5 SOP for Storing Electronic Digital Records and Data on Server (as per GAMP 5)

6 Ragulatries Checklist

Integrated Factory Automation

In a modern pharma facility, data shouldn’t exist in silos. Our expertise lies in creating a seamless flow of information from the sensor on the machine to the report on the CEO’s desk. We specialize in the convergence of Operational Technology (OT) and Information Technology (IT) to build a “Smart Factory” that is self-aware and data-driven.

We integrate PLC (Programmable Logic Controllers) and SCADA systems directly with BLINE AUTOMATION SUITE and BLINE PHARMA SUITE layers. This ensures that production data is captured at the source, eliminating manual data entry and “he-said-she-said” reporting.

Gain immediate visibility into Overall Equipment Effectiveness (OEE). Our dashboards track availability, performance, and quality in real-time, allowing you to identify bottlenecks, reduce downtime, and maximize machine throughput.

We design and implement automated control loops for critical parameters like temperature, pressure, and humidity, ensuring that your manufacturing process remains within validated states at all times.

In an interconnected factory, cybersecurity is paramount. We implement robust “Defense-in-Depth” strategies to protect your OT network from external threats while ensuring all automated data follows ALCOA+ principles.

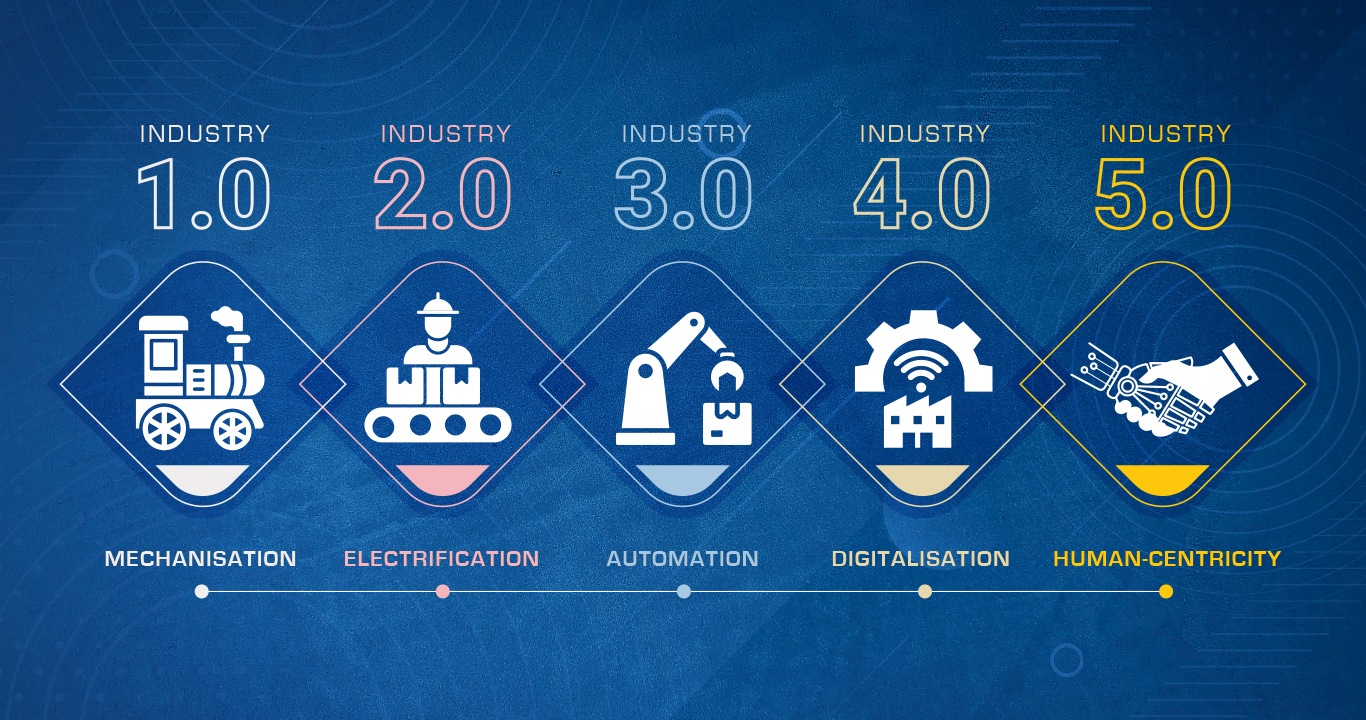

Bline Pharma Suite 4.0:

Our Future-Ready Unified Platform serves as a centralized digital ecosystem, empowering manufacturers to manage the entire spectrum of production and compliance within a single, cohesive interface. Architected specifically for the global life sciences industry, our solution eliminates data silos by integrating Batch Control, WMS, LIMS, and QMS into a high-performance framework. To ensure your facility is audit-ready at all times, the platform is rigorously aligned with GMP and major international mandates—including US FDA 21 CFR Part 11, EU GMP Annex 11, and PIC/S standards. By bridging the gap between shop-floor automation and enterprise governance, we provide the real-time visibility and absolute data integrity required to navigate the complexities of modern pharmaceutical manufacturing with confidence and speed.

Regulatory Alignment

– US FDA 21 CFR Part 11: Robust electronic signatures, time-stamped audit trails, and strict data security protocols.

– EU GMP Annex 11: Full compliance with European standards for computerized systems in regulated environments.

– PIC/S Standards: Alignment with the Pharmaceutical Inspection Co-operation Scheme for international quality consistency.

– GAMP 5 (Category 4 & 5): Following a risk-based approach for the development and validation of automated systems.

– ALCOA+ Principles: Ensuring data is Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, and Available.